How To Use Neje Engraver For Mac

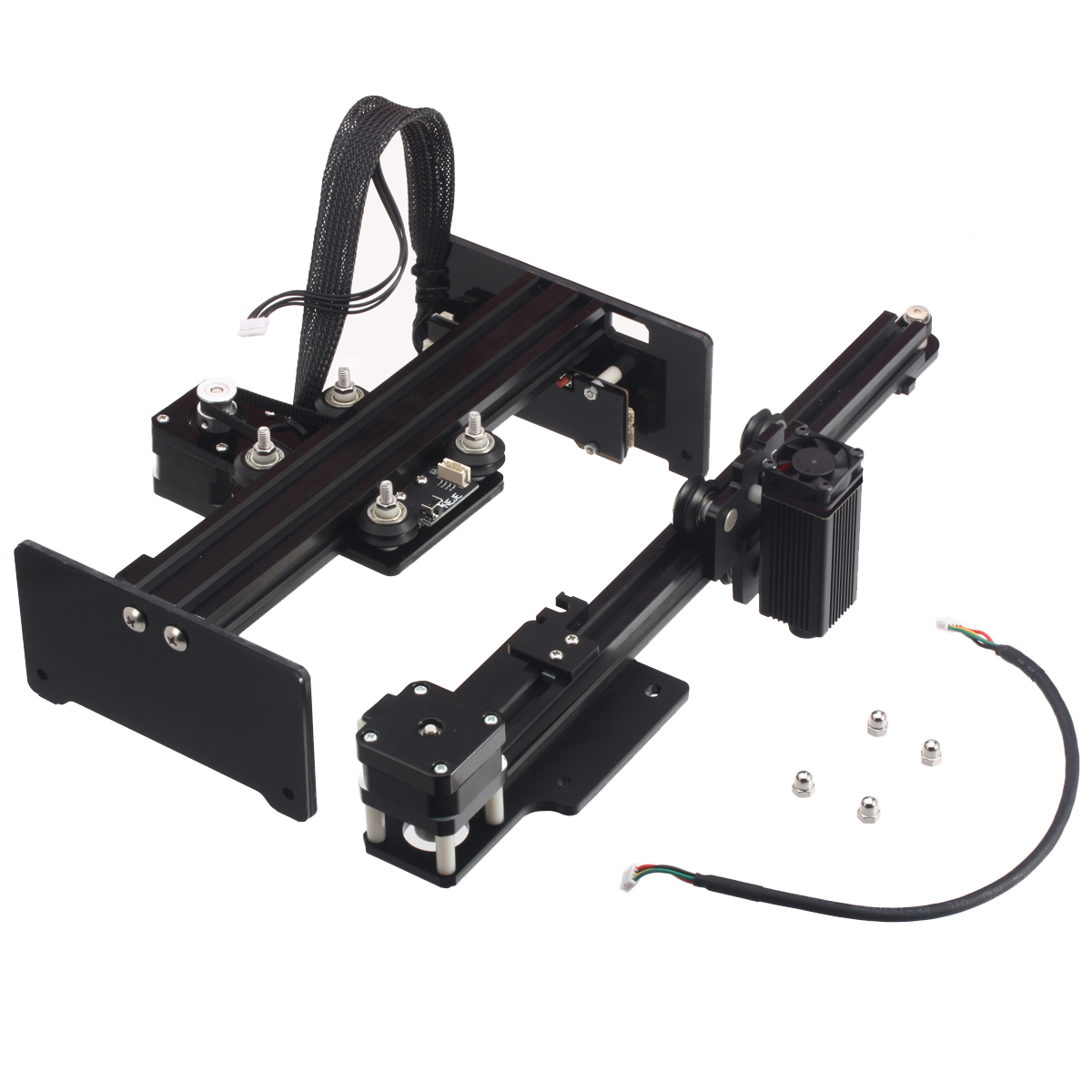

Introduction: NEJE DK - 5 Pro 500mW USB DIY Mini Laser Engraver - USER MANUAL

Step2: download 2019 SoftwareNEJEV4.2(update at 2019/1.31) or 2018 SoftwareV4.0. Step3: install.net framework (If you have already opened the software, you can ignore this step) If you get the following error, you need to install the Microsoft.net operating environment. Follow the steps below to install.

NEJE DK-5 Pro-5 is a laser engraver/cutter What can you do with it? Engraver something on plastic, mobile case, bamboo,wood, cardboard and cut paper and foam. Image size up to 38 x 38mm. and laser power is 500mW.

where you can buy it from Gearbest.Here is the link: http://goo.gl/hczb9q Or http://goo.gl/hczb9q

Teacher Notes

Teachers! Did you use this instructable in your classroom?

Add a Teacher Note to share how you incorporated it into your lesson.

Step 1: Main Features & Specifications

Main Features:

● Support our professional English design software.

● 10 times faster engraving.

● Strong and cool design, high precision and stability.

● Unique frame and weak light automatic positioning, frame positioning makes the image positioning easier, weak light even would not be difficult to engrave in toothpicks.

● High power and high resolution print, soft material can print out the 3D and the gradient effect.

● Long time use, NEJE developed the professional power IC and radiator, carving time will last much longer than other laser and more stable.

● Truly 500mW blue and purple laser head, more higher speed, support more types of materials.

● Can be carved items included: Hard wood, plastic, bamboo, rubber, leather, cut paper and so on.

● Can not engrave metal / aluminum / acrylic.

● Material: Acrylic + aluminum + stainless steel.

● Image size up to 38 x 38mm.

● Support Win 7, XP, Win 8, Mac system.

● Free software download link:http://www.trusfer.com/#Download

Specifications:

Dimensions and Weight - Product weight: 1.000 kg , Product size: 13.00 x 13.50 x 16.50 cm / 5.12 x 5.31 x 6.5 inches

Step 2: Packing Contents

1 x Engraving Machine

Reprise double-disc set of the same name issued in 2002. This is a stripped-down single-CD equivalent to the U.S.  And for a single CD it does a fair job of covering the major touchstones in the history of a band with a four-decade legacy - or, at least, of 's two best-known incarnations, as a mid- to late-'70s pop/rock outfit and a late-'60s blues-rock band.

And for a single CD it does a fair job of covering the major touchstones in the history of a band with a four-decade legacy - or, at least, of 's two best-known incarnations, as a mid- to late-'70s pop/rock outfit and a late-'60s blues-rock band.

1 x Laser Protective Glasses

1 x Micro SD Card (1GB)

1 x Mini USB Data Cable (0.8m)

1 x USB A-A Power Cable (1.2m)

1 x Power Adapter (5V 1A US Plug)

1 x Allen key

Step 3: Engraving Process

Before you can use a computer and printer for printing , you need to install printer driver which

allow the printer communicate with the computer, furthermore you need to install application software on your computer so that you can start your printing. The same situation applies to the Laser Engrave, you need to install the USB-Serial driver which allow the Laser Engrave talk to the computer, and you need to install the engraver software in order to control the Laser Engraver. DK-5 Pro-5 engraver come with a 1GB micro SD card, the files on the SD card including the USB-Serial driver, engraver software and few JPG photos as shown in figure below. The software can be running on Win XP, Win 7, Win 8 ,Win 10,system. Alternately, the software can be download from the link below: http://www.trusfer.com/#Download

Alternately, the software can be download from the link below:http://yunpan.cn/cmX7QiZHXWThg (password for download: 864b).

Step 4: Driver Setup

As mentioned above, the SD card consisting of the USB-Serial driver that you can install into your computer.

1. Do not connect the Laser Engraver to your computer.

2. Copy all the folders & files from SD card to your computer.

3. Browse to the folder until you see the Driver.exe executable file.

4. Double-clicking the Driver.exe file, the driver setup menu should open up.

5. Click on the INSTALL button to start the driver installation

6. Connect the Laser Engraver to computer via a Mini USB data cable (without

connect the USB A-A power cable), your computer should detected the

·

1.Connect:Make sure your systeam is right, and connect the right com port.

2.Power:Make Sure the input power is 5V1A, if Stop when in the process of carving, This kind of phenomenon is because the computer usb power supply shortage.

3: Focus:Carving the focal length of the different object is different, need to adjust the focal length of the laser

Step 5: Check If the Driver Is Installed Correctly.

Open 'Device Manager' from the Windows 'System Properties', check to see whether the driver is installed correctly.

Step 6: Connecting the NEJE DK-5 Pro-5 to Computer (PC)

The 5V 1A power adapter is connected to the laser engraver via a USB A-A cable, and the data port on laser engraver is connected to the computer's USB port via a Mini USB cable.

Step 7: Prepare Images for Engraving

The Micro SD card containing sample images with resolution 512x512 pixels. In the future, you may use your own images for engraving, it is advised to convert the images to black and white colour & adjust the image size to 500*500 pixels.

Step 8: Safety & Adjusting Focal Length

Laser can be very dangerous to the eyes, please wear protective glasses when engraving.

*Adjusting focal length

Before engraving, make sure adjust the focus of the laser lens corresponding to the thickness of the material

Step 9: How to Use Software

- The laser engraver software for NEJE DK-5 Pro-5 does not need an installation, you can run it from your SD card. Double clicking the 'Laser Carve_EN 2015.11.10.3.0.0.exe' file should run the software, the picture below shows the main screen of the software.

How to use the software

§ Drag an image to the engraver preview window

§ Click on 'Send image to Machine' to send the image to the engraver controller

§ Before you start carving, you may want to click on the 'Carving Preview' button in order to see if the object is placed to the correct position. This is especially useful when you want to carving tiny materials such as toothpick, chopstick, etc.

§ Clicking on the 'Start' button, the machine should start carving.

§ You can pause the machine any time by clicking on the 'Pause' button. This is especially useful when you want to see how is the unfinished carving result.

§ If the engraver machine already go into a PAUSED state, you must click on the 'Start' button in order to continue carving.

Be the First to Share

Recommendations

Rubber Band Speed Challenge

Woodworking Contest

Trash to Treasure Contest

How-to's and resources for upgrading the NEJE (also sold under the HICTOP brand, and others) desktop USB laser engraver to full GRBL compatibility by replacingthe electronics.

Last updated January, 2018.

Full grbl upgrade with Arduino CNC Shield

Videos

I have uploaded a video of the whole upgrade process at youtu.be/2rbzI-d-bOA.

A second video with specific focus on the wiring, and that covers use of aMOSFET to switch the laser, is also available at https://youtu.be/MuKYvifYnYs.

Links to resources

Software-only upgrade

If you are lucky enough to have a machine that can be upgraded without replacingthe board, you can follow these instructionsto flash a new version of grbl to it.

Hardware

The engraver pictured above and in the video: KKmoon NEJE DK-8-KZ 1000mW

The Arduino shield used to control the steppers: Arduino CNC Shield.I think I mistakenly referred to this as 'grblshield' in the video.

Arduino Uno, the board that connects to the shield above.

Laser focus adjustment ring.

IRF520 module, the board thatcontrols power to the 5V laser.

Software

Universal Gcode Sender -Used to send commands to the laser.

J Tech Photonics Laser Tool -Used to convert images to laser commands.

Wiring diagrams and schematics

Connecting PC power supply to Arduino and Shield

The CNC shield can accept any DC voltage from 12V to 36V. Because the steppermotors used here are very small, the 12V does not need to be high amperage;500ma or larger will probably be sufficient.

To power the upgrade, I used a power supply designed to run an internal PChard drive, although a full-size PC power supply would work.

The most important part of the power supply is that is can give 5V at severalamps to power the laser.

The CNC shield electronics can then be powered from 5V as well, but I choseto power them from the 12V rail of the power supply. If you choose to do that,you will want to adjust the current-limit on the drivers to avoid damaging thestepper motors. Details of how to do this are in the video.

Connecting stepper motors to the shield

The connector for the stepper motors are between the 'drivers' (the red squarecircuit boards in this image.

With the white wire facing up, match the 4-pin connector on the cable to the4-pin connector on the board for both the X- and Y-axis.

Connecting laser to power supply and CNC shield

The SPNEN (SPiNdle ENable) pin on the shield cannot power the laser itself, soI use a circuit with a transistor to power the laser from the power supply, butstill allow it to be turned on and off by the CNC shield.

First, you will connect the positive wire of the laser (coloured red on mine) tothe 5V power line from your power supply. It MUST be 5V, any more will damagethe laser!

We will switch the laser on and off by connecting or disconnecting thenegative/ground wire. This technique is known as 'low-side switching'.

Here are two ways to do it, though there are probably other ways too. Irecommend using a MOSFET over a TIP120. But if you only have a TIP120 it willstill work though your laser power may suffer.

MOSFET circuit

An efficient way to switch the laser on and off is to use an N-Channel PowerMOSFET. Currently I am using an IRF520 module like this one, but this is not designed for logic-level switching so if you have the option I wouldrecommend using a logic-level MOSFET instead.

But, regardless of the voltage, if you want to solder one yourself then thecircuit will look something like this:

This will switch the laser on and off with a minimum of voltage loss.

If you use the same IRF520 module that I did, here is how the wires areconnected:

TIP120 circuit

Before using the MOSFET, I was using a TIP120 Darlington transistor. This worksbut it is a poor choice because the voltage drop on a TIP120 can be as much as2V in some cases. If we were switching 48V then that wouldn't be a problem butfor a 5V laser, losing even 1V is going to severely impact laser power.

Here is the TIP120 switching circuit I used before:

The transistor I used is a TIP120 'Darlington' transistor. It is a very common'power transistor' that you can find at any electronics shop (Radio Shack,Fry's, etc) and everywhere online. You can use any similar NPN-type powertransistor (such as the TIP31, etc) as long as it can handle the current. Astandard 2N3904 transistor can't handle it, and while a 2N2222 may be able tohandle it for lower-powered lasers, I would still recommend using a TIP-series transistor because they are still very inexpensive.

Note: I should really upgrade the above circuit to use a MOSFET insteadof a power transistor. It shouldn't be that hard adapt it usingthe example from this page. It may alsolet us use PWM to control the intensity of the laser.

Orientation

The origin (X/Y at 0) coordinates should be at the lower-left of the of thestage. 'Lower' here means nearest to front. Make sure moving each axisnegatively will move toward that point, and moving each axis positively willmove away from that point.

configuring grbl to work in positive space

For J Tech Photonics Laser Tool (in Inkscape), make sure to set the machinecoordinates system to operate in positive space. You will do that byuncommenting the following line in config.h before you upload the grblcode to the Arduino:

grbl 1.1 settings for Arduino CNC Shield upgrade

Reset default work area

You will probably need to reset the default 'work area'. Do that with thesetwo commands: